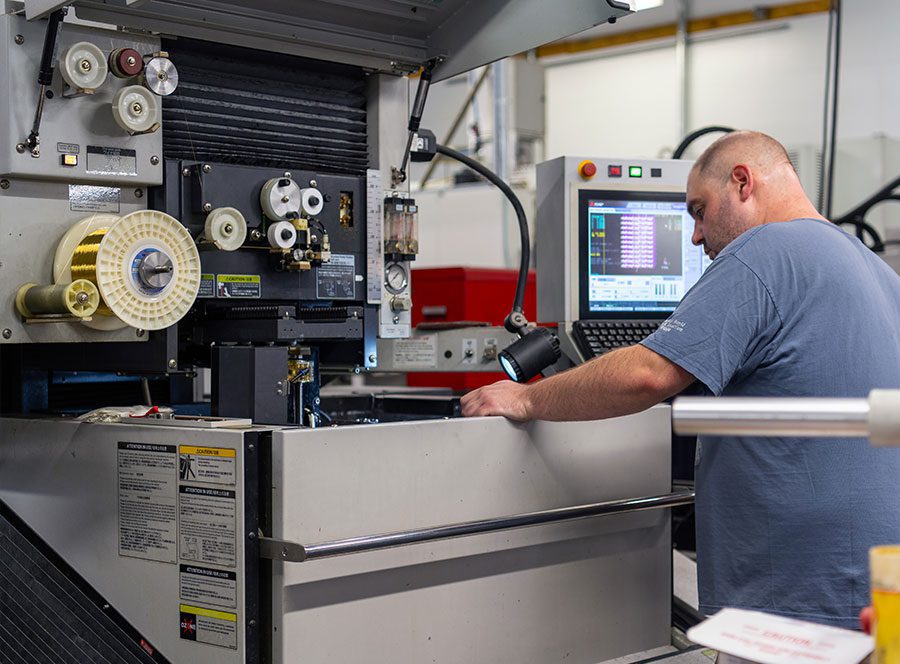

CNC EDM

Bradford also offers Electrical Discharge Machining (EDM), an innovative manufacturing process. EDM uses electrical discharges to cut and drill incredibly complex and precise shapes into any electrically conductive metal. This process easily achieves tolerances of -.0002″, provides excellent finishes up to 8 RMS, and leaves no stresses or burrs in the material. Parts such as precision gauges, keyways, gears, splitting tubes, internal splines, and cams are perfect for this process.

- Mitsubishi MD+PRO III MV1200s Wire EDM, maximum workpiece size 31.9″ x 27.6″ x 8.5″, .000002″ glass scale resolution, .006-.012″ wire

- Sodick AQ535L High Speed CNC Wire EDM. 21.5″ x 13.7″ travel x 11.8″ High, .000004″ glass scale resolution. .006-.012 wire size. (2004)

- Perseo DrillMate SD24NC EDM w/ Drilling and Thread Tapping Functions, 15.7″ x 9.8″ travel x 15.7″ high

- Perseo Drillmate DM22i High Speed EDM Drill, 15.7″ x 12.4″ travel x 11″ high, hole diameters from .004″ to .125″

- Mitsubishi MD+PRO III MV1200s Wire EDM, maximum workpiece size 31.9″ x 27.6″ x 8.5″, .000002″ glass scale resolution, .006-.012″ wire

- Sodick AQ535L High Speed CNC Wire EDM. 21.5″ x 13.7″ travel x 11.8″ High, .000004″ glass scale resolution. .006-.012 wire size

- Perseo DrillMate SD24NC EDM w/ Drilling and Thread Tapping Functions, 15.7″ x 9.8″ travel x 15.7″ high

- Perseo DrillMate DM22i High Speed EDM Drill, 15.7″ x 12.4″ travel x 11″ high, hole diameters from .004″ to .125″

- Sodick A325L

Full Machining Capability List

“Prince has been a strategic supplier of ours for the past 20 years.”

Global Sourcing Manager

Large OEM Manufacturer